The Van der Graaf Drum Motor

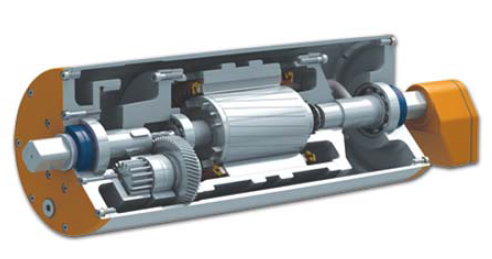

The Van der Graaf Drum Motor is a one component conveyor drive where the motor, gear drive and all moving parts are enclosed inside the drum. The motor and gears operate in a sealed oil bath ensuring proper lubrication and cooling. With no external motor, gear reducer, sprockets, chain, or OSHA required chain guard, no external component maintenance is required. This reduces operating and maintenance costs, improves safety conditions, and because it is completely sealed our drum motors can operate in extreme environmental conditions. Our Sanitary Series Drum Motors are able to withstand extreme pressure wash down using sanitizer without the need to shield sensitive components since the completely sealed drum motor has no external components to protect.

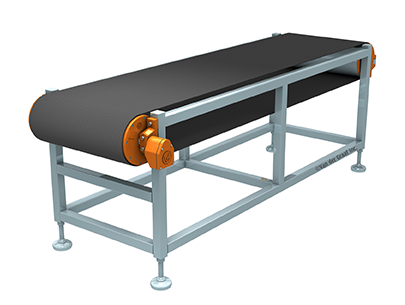

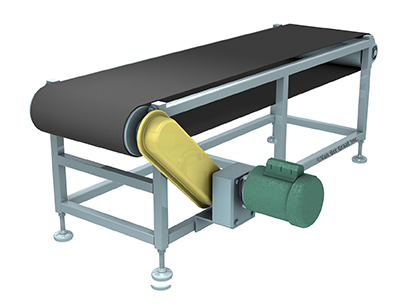

The rugged design of the Van der Graaf drum motor is space saving, quiet, efficient and reliable with virtually no maintenance. It offers a versatile, less complex and more efficient way to power your belt conveyor.

Standard drum motors are available in mild steel or stainless steel construction, in a wide range of diameter sizes, belt speeds, horsepower and face widths to suit broad range of applications. The electric motor is available in all voltages and frequency suitable for most applications.

- Sanitary Handling Antimicrobial Series Drum Motors

- Drum Motor for Modular Belt Conveyors

- Explosion Proof Drum Motors

- Idler Rollers

- Extreme Duty Series Drum Motors

Van Der Graaf Drum Motor

Conventional drive installation

The Drum Motor eliminates the external components such as motor, gear box, sprockets, chain, chain guard and pillow block bearings typically seen on conventional drives. All external component maintenance is eliminated by having the electric motor, gear drive and all moving parts of the drum motor enclosed inside the drum. The motor and gears operate in a sealed oil bath enclosure, ensuring proper lubrication and cooling. The drum motor rotates a gear module which transmits power to the outer rotating drum.

The compact low-profile design of the drum motor provides the end user a safer and quieter working environment, space savings, efficiency and reliability with virtually no maintenance. Installation is quick and easy requiring less time to install than exposed conveyor drives.

RELATED DOCUMENTATION

Van Der Graaf Drum Motors

Product Guide

Media F650 - Published in 2013

A guide to the features and benefits of a drum motor.

Van Der Graaf SSV Series

SSV Series Drum motors

Published in 2018

Specifications on SSV series drum motors.